Failing Crude Oil Pipeline Threatening Croatian Farmland Replaced with Innovative Steel-Reinforced Line Pipe

The Challenge

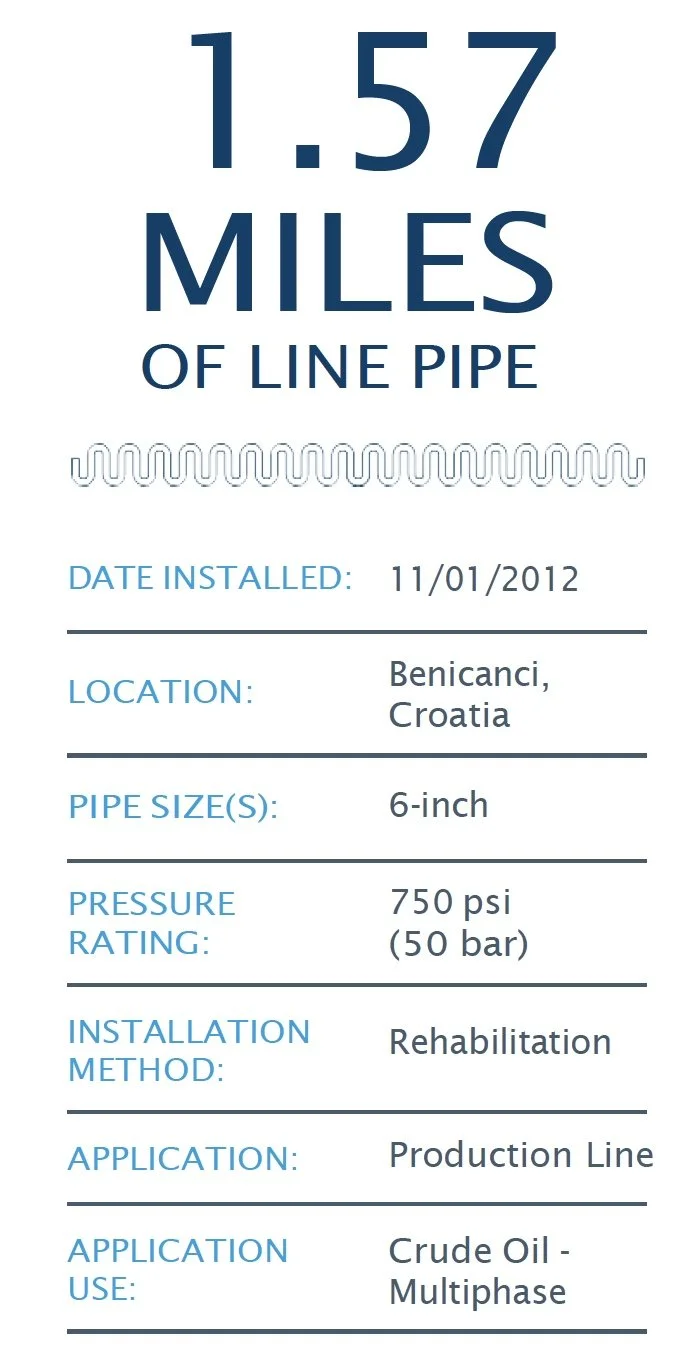

In January 2013, a major oil and gas operator needed to rehabilitate 1.57 mi (2.53 km) of its pipe in Benicanci, Croatia. The pipeline, which had transported multiphase crude oil since 1987, was in danger of rupturing, which could result in damage to the local farmland and water channels. Racing against the sub-freezing winter conditions, the company needed a solution that would minimize impact to the farmland and allow them to recommission their corroded steel pipeline.

The Solution

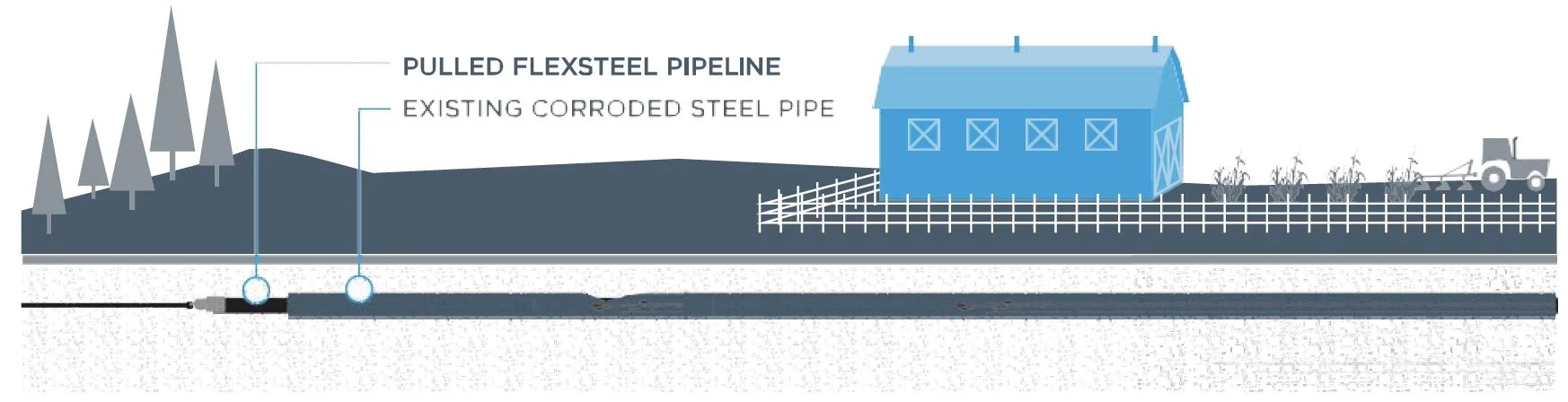

Using FlexSteel 6-inch 750-psi line pipe, the operator opted to pull the spoolable steel-reinforced pipeline through their damaged steel line. By positioning FlexSteel’s reels near the carrier pipe, the operator could deploy the pipe through the existing steel line. Since FlexSteel can be pulled though several thousand continuous feet of buried carrier pipe, the operator would only have to excavate the existing line in strategic access points, minimizing disturbance along the right-of-way. Working with a hydraulic winch unit, the operator would be able to monitor the real-time force applied to the pipe, thereby ensuring it would not exceed the maximum allowable installation tension.

The Result

Due to the superior tension capabilities of FlexSteel pipe, its corrosion resistant design, and the ease of installation, the operator realized several key operational benefits:

Rehabilitation of the failing steel pipeline before harsh weather conditions delayed or suspended operations.

Installation of the pipe with fewer access points.

Minimal equipment-related disturbances on the right-of-way.

Minimal work vehicle traffic to and from the job site.