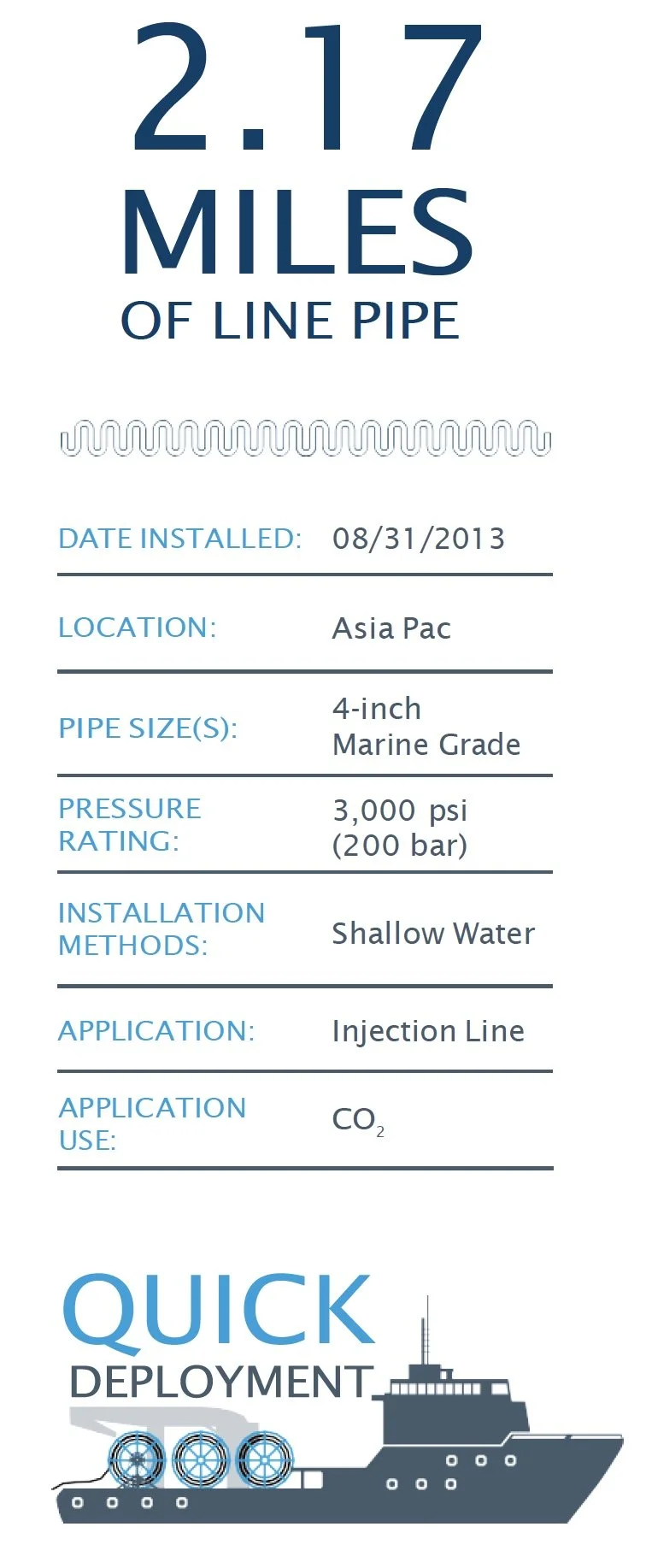

FlexSteel Pipe Installation Spares Malaysia Operator Costly Weather Delays

The Challenge

As part of an effort to increase oil recovery, a Malaysian operator working off the coast of South Vietnam wanted to install a 2.17-mi (3.5-km) CO2 injection line between its production and well platforms. The operator required that the line be installed directly along the ocean floor at a depth of 164 ft (50 m). While the installation project was originally scheduled to take place during a time of year when favorable weather would provide optimum working conditions, unforeseen delays pushed the start of installation into the region’s typhoon season. To overcome the difficult working conditions, the company needed a solution that would enable them to install a pipeline system during short breaks in the severe weather that was dominating the area.

The Solution

To provide a solution that would meet the operator’s installation requirements, FlexSteel recommended its 4-inch, 3,000 psi (200 bar) Marine Grade steel-reinforced line pipe. Due to the pipe’s negatively buoyant design, the pipe would provide the operator with a subsurface gas injection line with the durability to resist highly corrosive applications while eliminating the need for complex anchoring systems on the sea floor. The pipe was loaded on a roller system aboard a dynamic positioning vessel for deployment at sea. The nine reels of the Marine Grade pipe necessary for the job could be accessed whenever needed without employing a crane. Operating from one vessel would enable an installation crew composed of two FlexSteel technicians and three riggers to quickly deploy the pipe during short breaks in the severe weather.

The Result

Despite 20 days of weather delays and short favorable weather windows that dictated 5 -day critical path schedules, the pipeline was installed in six weeks. In addition, the smaller installation crew substantially reduced the costs typically associated with subsea installation.

Working closely with the operator and the installation contractor, FlexSteel helped ensure the pipeline was installed safely and efficiently. When the project was completed, the operator and contractor remarked that the installation characteristics of the negatively buoyant FlexSteel Marine Grade pipe and the support FlexSteel provided exceeded their expectations.