Steel-Reinforced Dual-Gas Pipeline Installed Under Turbulent Congolese Coastal Waters in Three Days

The Challenge

A large oil and gas company required the installation of a 6-in. dual-gas pipeline off the Congolese coast in an area known for large wave swells and severe turbulence. It was essential to install the pipe quickly to avoid hazardous sea conditions and to minimize costly installation vessel time. The project requirements called for dual 6.21-mi (10-km) gas lines to be installed at water depths ranging from approximately 150 to 195 ft (46 to 59 m). Accordingly, it was essential that the pipe installed remain at the required operational depth. In addition, if a spoolable option was selected, the pipe had to be flexible enough to be pulled through a J-tube or an I-tube for connection to the platform riser.

The Solution

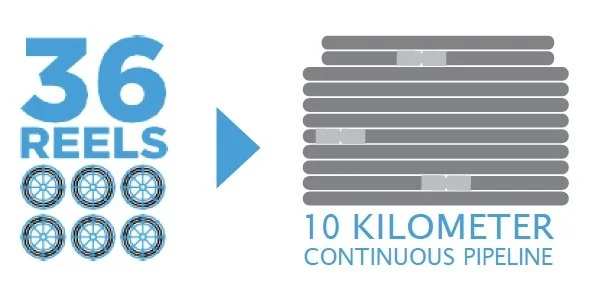

FlexSteel suggested its negatively buoyant Marine Grade pipe, which features a flexible steel-reinforced core for increased durability, for the company’s application. To make the install, FlexSteel assembled each 6.22- mi (10-km) pipeline by connecting 36 reels of FlexSteel 6-inch Marine Grade line pipe with 35 midline connections. The FlexSteel team worked closely with the company to leverage the pipe’s flexible design and provide a deck layout that would minimize vessel space and reduce installation time. Each pipeline was loaded into a carousel in three days while the vessel was docked. By using one continuous 6.22-mi (10-km) pipeline, the operator would be able to transport pipe to the installation site and quickly deploy it, substantially reducing the number of return trips to shore or supply vessels for more pipe.

The Result

Once the vessel arrived at the offshore installation site and performed the required dynamic positioning trials, pipeline installation took only three days, including subsea stabilization. The company noted that the project was conducted safely and with the efficiency necessary to meet all schedule and budget requirements.