US National Parks Service Utilizes Flexible Steel Pipe for Fresh Water Distribution

Date Installed:

June 2024

Location & Region:

Arizona, US

Product Used:

3 inch, 1500 PSI

Application:

Fresh Water Distribution

Project Overview

Aluminum pipelines supplying fresh water in the Grand Canyon were breaking, on average, once a month. Repairs were costly, and it took up to 5 days to restore service for each repair.

Key Points:

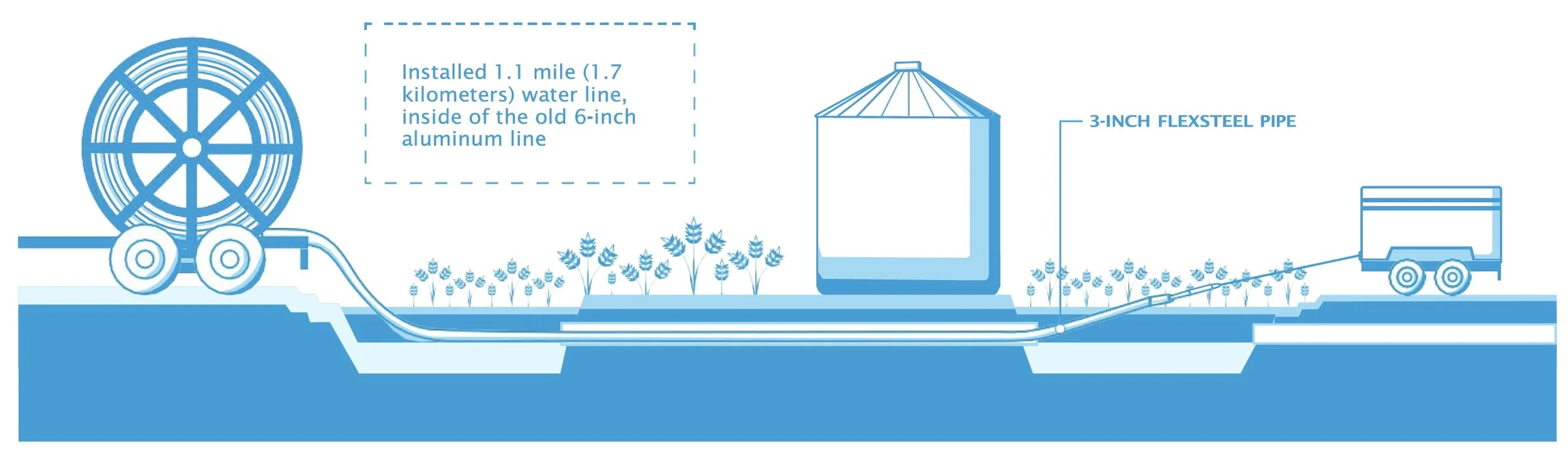

3-inch 1500 psi FlexSteel pipe was pulled through a corroded 6-inch aluminum pipeline.

A custom anchoring system was designed to suspend installation technicians from cliffs.

Pipeline rehabilitation was accomplished quickly with minimal disruption to the environment.

The new FlexSteel lines will provide reliable, maintenance-free service for many decades.

The Challenge

The US National Parks Service (NPS) needed to repair a more than 50-year-old line that provided fresh water to hikers in Grand Canyon National Park. Constructed in the 1960s of aluminum, the line had exceeded its projected 30-year design life and was breaking once a month, on average. Such breaks cost approximately $25,000 to repair and interrupt the flow of water for up to five days. During a break, Phantom Ranch, Indian Garden and the South Rim become dependent on stored water, requiring visitors, residents, and commercial operators to increase water conservation measures.

The line crosses areas where the terrain is environmentally sensitive and difficult to traverse, which makes it challenging to service the South Rim and Cross Canyon Corridor. Aluminum pipe had been selected for the original water line because its weight-to-size ratio made it easier to haul over the difficult terrain. However, the aluminum material also contributed to the degradation of the waterline and frequent structural breaks.

The Solution

To address the problem, the NPS staff and civilian engineers developed plans to address the aging pipeline system. As a result, the Transcanyon Water Line (TCWL) project was established to modernize the water delivery system and its associated infrastructure. A team of NPS engineers, engineering consultants, and U.S. Public Health officers analyzed numerous types of pipe materials to replace the water distribution system.

According to the engineer who led the initiative, “The team selected FlexSteel pipe because of the balanced tradeoff between weight to durability and the strength of the material. The complexity of the inner canyon’s access and environmental conditions has made the selection of materials and equipment absolutely critical in balancing design and constructability while mitigating the impact to cultural and natural resources.”

FlexSteel’s 3-inch 1500 psi pipe was selected to restore the Grand Canyon’s water service. The new pipe was installed by pulling it through the old 6-inch aluminum pipeline. This installation method eliminated the need to dig up and remove the old pipe and minimized disruption to the environment. To install the pipe in mountainous areas, the TCWL project team, in collaboration with FlexSteel Engineering Technical Services, engineered an anchoring system to support the FlexSteel pipe from the cliffs.

The Result

Water service in the park was restored quickly using 3-inch 1500 psi FlexSteel pipe, eliminating concerns about disrupted water service and leak repairs in hard-to-access areas for many decades. Additional planned TCWL improvements include replacing distribution pipe and water stations, and building a small water treatment plant, pump station and raw water tank.

As a result of the success with the 3-inch pipe installation, NPS has selected 8-inch FlexSteel pipe to replace approximately 18,000 feet of 6-inch aluminum pipe. Furthermore, the NPS has purchased 4-inch 1500 psi and 6-inch 1500 psi FlexSteel pipe for use as temporary bypass lines to use while work is being done throughout the TCWL infrastructure.